How Do Laser Gyroscopes Enhance Navigation Accuracy?

2025-09-16

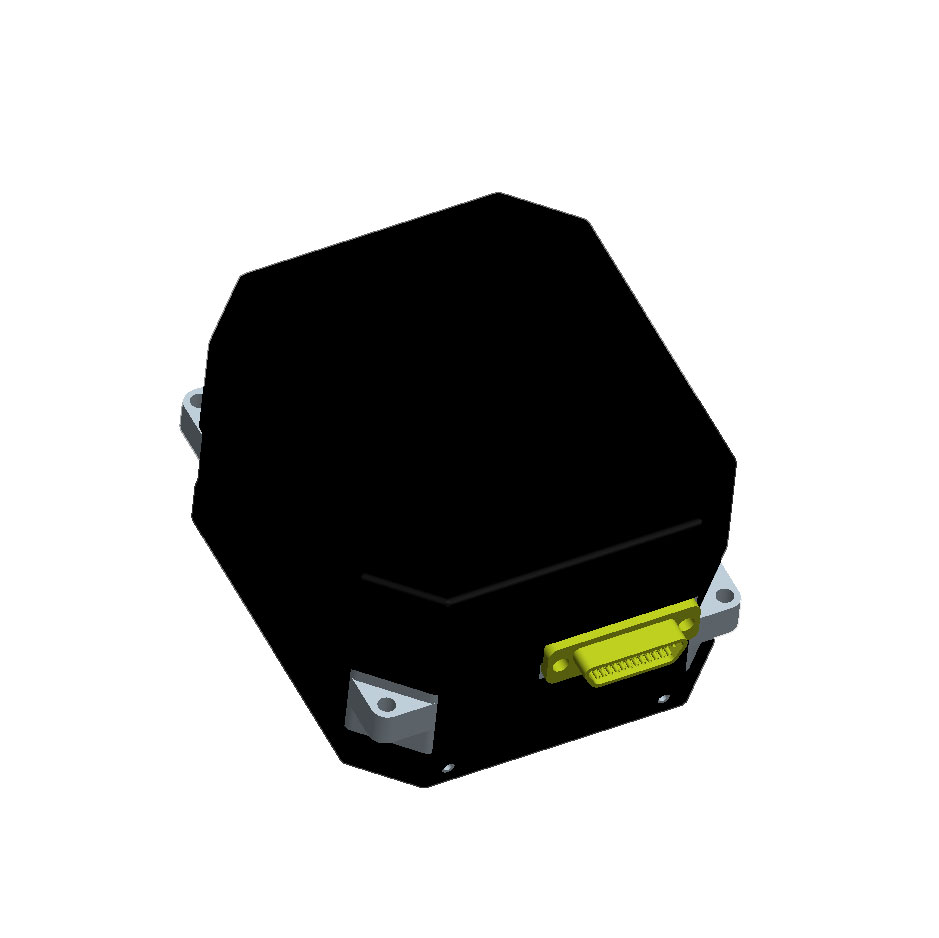

Accurate navigation is a cornerstone of modern technology, spanning industries from aerospace to defense, shipping, automotive, and even consumer electronics. One of the most advanced tools enabling precise navigation is the laser gyroscope, also known as a ring laser gyroscope (RLG). Unlike traditional spinning-mass gyroscopes, laser gyroscopes rely on the interference of light beams to detect angular rotation. This allows them to measure changes in orientation with extreme accuracy and without the wear and tear associated with moving parts.

The basic working principle of a laser gyroscope is rooted in the Sagnac effect, discovered in the early 20th century. When two laser beams travel in opposite directions along a closed loop, any rotation of the system causes a measurable phase shift between them. This shift is directly proportional to the rate of rotation, making it possible to track angular movements in three-dimensional space.

Why are laser gyroscopes so widely adopted? The reasons are clear:

-

High precision: Capable of detecting even the smallest angular deviations.

-

Durability: With no moving mechanical parts, they offer long-term reliability.

-

Compact design: Suitable for both large-scale aerospace systems and smaller mobile platforms.

-

Versatility: Equally effective in space, air, land, and sea applications.

From guiding aircraft safely through turbulence to ensuring submarines maintain stealth navigation underwater, laser gyroscopes are indispensable in applications where GPS signals may be unavailable or unreliable.

How Do Laser Gyroscopes Work Across Applications?

While the fundamental principle is based on the Sagnac effect, the engineering behind laser gyroscopes ensures they are adaptable to different operational demands.

Key Working Mechanism

-

Laser Beams in a Cavity

Two laser beams are generated and travel in opposite directions along a closed optical path. -

Interference Measurement

As the system rotates, the effective path length for each beam changes, leading to a frequency difference between the two beams. -

Signal Conversion

This frequency difference is converted into an electrical signal, which represents the rate of rotation.

Advantages Over Conventional Gyroscopes

-

No moving parts reduce mechanical drift and maintenance costs.

-

Higher measurement stability under extreme environmental conditions.

-

Long operational lifetimes, even in demanding aerospace or defense missions.

Industry Applications of Laser Gyroscopes

-

Aerospace: Aircraft, helicopters, and spacecraft rely on laser gyroscopes for precise navigation in GPS-denied areas.

-

Maritime: Submarines and naval vessels use them for underwater navigation where GPS cannot penetrate.

-

Military and Defense: Essential for missile guidance, armored vehicles, and tactical systems.

-

Geoscience: Used in earthquake detection, drilling, and geophysical surveys.

-

Autonomous Systems: Supporting driverless cars and unmanned aerial vehicles in navigation accuracy.

Technical Parameters of Laser Gyroscopes

Below is a professional overview of typical specifications:

| Parameter | Specification Range / Options |

|---|---|

| Measurement Range | ±500 °/s to ±1000 °/s depending on model |

| Bias Stability | < 0.001 °/h for high-precision systems |

| Scale Factor Accuracy | Up to ±10 ppm |

| Operational Temperature | -40°C to +70°C |

| Power Consumption | 5 W – 20 W depending on size and performance |

| Dimensions | Compact modules (50 mm) to large-scale aerospace-grade units |

| Output Interface | Digital or analog signal, customizable integration options |

These parameters ensure that laser gyroscopes can be tailored for everything from satellites in orbit to field equipment in rugged terrains.

How to Select the Right Laser Gyroscope for Your Needs?

Choosing the right laser gyroscope is a critical decision for any business or project requiring precision navigation. The wrong choice could lead to system inefficiency, operational errors, or costly failures. Careful evaluation of specifications, environment, and intended use is essential.

Key Considerations in Selection

-

Application Environment

-

For aerospace: prioritize lightweight, high-accuracy models.

-

For defense: ruggedized models with extreme temperature resistance are crucial.

-

For geoscience: gyroscopes with ultra-low drift are preferred.

-

-

Bias Stability Requirements

-

Ultra-stable gyroscopes (<0.001 °/h) are necessary for long-duration missions without recalibration.

-

-

Size and Weight Constraints

-

Space-limited platforms like UAVs benefit from compact units.

-

Submarines and ships may accommodate larger models for added robustness.

-

-

Integration and Compatibility

-

Ensure compatibility with existing navigation systems, including IMUs (Inertial Measurement Units).

-

-

Budget and Lifecycle Cost

-

While high-end gyroscopes have higher upfront costs, their durability and precision can reduce long-term operational expenses.

-

Benefits of Choosing the Right Gyroscope

-

Improved navigation safety.

-

Reduced reliance on external systems like GPS.

-

Enhanced operational efficiency and reliability.

-

Lower maintenance and replacement costs.

Common FAQs About Laser Gyroscopes

Q1: How do laser gyroscopes compare to fiber optic gyroscopes (FOGs)?

A: Both laser gyroscopes and fiber optic gyroscopes use the Sagnac effect. However, laser gyroscopes typically provide higher accuracy and lower noise levels, making them ideal for critical aerospace and defense applications. FOGs, while less expensive, are often chosen for commercial or mid-range precision needs.

Q2: How long do laser gyroscopes last in operation?

A: Thanks to their solid-state design with no moving parts, laser gyroscopes can last for decades under proper conditions. Aerospace-grade gyroscopes often function reliably for 15–20 years without significant performance degradation, provided they are maintained within specified environmental parameters.

How Are Laser Gyroscopes Driving the Future of Navigation?

As industries demand ever-higher precision in navigation, laser gyroscopes are playing a central role in shaping next-generation systems.

Emerging Trends in Laser Gyroscope Technology

-

Miniaturization: Compact gyroscopes are being developed to support drones, autonomous vehicles, and handheld geoscience equipment.

-

Integration with AI-driven Navigation Systems: Coupled with advanced software, laser gyroscopes provide real-time data fusion with accelerometers and GPS for unmatched accuracy.

-

Space Applications: Satellites and spacecraft rely increasingly on high-precision gyroscopes for deep-space navigation where GPS is not available.

-

Sustainability and Efficiency: Improved energy efficiency ensures longer operational life in battery-dependent systems.

The Long-Term Importance of Laser Gyroscopes

Even as technology evolves, the demand for laser gyroscopes continues to grow because of their proven reliability and accuracy. They serve as the backbone of inertial navigation systems, ensuring safe travel in air, sea, land, and outer space.

At jioptik, we specialize in designing and manufacturing high-performance laser gyroscopes engineered for aerospace, defense, maritime, and industrial applications. Our commitment to innovation and precision ensures that clients receive products tailored to their specific operational needs.

For detailed technical specifications, customized solutions, or bulk orders, we invite you to contact us today and learn how jioptik can support your navigation and sensing requirements with world-class laser gyroscope technology.